Basics

In this example we first simulate an APC Thin-Electric 10x7 propeller operating in cruise conditions. Along the way, we demonstrate the basics of how to set up and run a rotor simulation.

Rotors are generated through the function FLOWUnsteady.generate_rotor, which can receive either a set of parameters that define the rotor geometry (like twist/chord/sweep distributions, etc), or it can read the rotor geometry from a file. FLOWunsteady provides a prepopulated database of airfoil and rotor geometries to automate the generation of rotors, which is found under database/. This database can be accessed through the variable FLOWUnsteady.default_database. Alternatively, users can define their own database with custom rotors and airfoils.

The following slides describe the structure of the database, using a DJI rotor as an example:

In this simulation we exemplify the following:

- How to generate a rotor with

uns.generate_rotor - How to generate a rotor monitor with

uns.generate_monitor_rotors - How to set up and run a rotor simulation.

#=##############################################################################

# DESCRIPTION

Simulation of an APC Thin-Electric 10x7 propeller (two-bladed rotor, 10-inch

diameter).

This example replicates the experiment and simulation described in McCrink &

Gregory (2017), "Blade Element Momentum Modeling of Low-Reynolds Electric

Propulsion Systems."

# AUTHORSHIP

* Author : Eduardo J. Alvarez (edoalvarez.com)

* Email : Edo.AlvarezR@gmail.com

* Created : Mar 2023

* Last updated : Mar 2023

* License : MIT

=###############################################################################

import FLOWUnsteady as uns

import FLOWVLM as vlm

import FLOWVPM as vpm

run_name = "propeller-example" # Name of this simulation

save_path = run_name # Where to save this simulation

paraview = true # Whether to visualize with Paraview

# ----------------- GEOMETRY PARAMETERS ----------------------------------------

# Rotor geometry

rotor_file = "apc10x7.csv" # Rotor geometry

data_path = uns.def_data_path # Path to rotor database

pitch = 0.0 # (deg) collective pitch of blades

CW = false # Clock-wise rotation

xfoil = true # Whether to run XFOIL

ncrit = 9 # Turbulence criterion for XFOIL

# NOTE: If `xfoil=true`, XFOIL will be run to generate the airfoil polars used

# by blade elements before starting the simulation. XFOIL is run

# on the airfoil contours found in `rotor_file` at the corresponding

# local Reynolds and Mach numbers along the blade.

# Alternatively, the user can provide pre-computer airfoil polars using

# `xfoil=false` and pointing to polar files through `rotor_file`.

# Discretization

n = 20 # Number of blade elements per blade

r = 1/5 # Geometric expansion of elements

# NOTE: Here a geometric expansion of 1/5 means that the spacing between the

# tip elements is 1/5 of the spacing between the hub elements. Refine the

# discretization towards the blade tip like this in order to better

# resolve the tip vortex.

# Read radius of this rotor and number of blades

R, B = uns.read_rotor(rotor_file; data_path=data_path)[[1,3]]

# ----------------- SIMULATION PARAMETERS --------------------------------------

# Operating conditions

RPM = 9200 # RPM

J = 0.4 # Advance ratio Vinf/(nD)

AOA = 0 # (deg) Angle of attack (incidence angle)

rho = 1.225 # (kg/m^3) air density

mu = 1.81e-5 # (kg/ms) air dynamic viscosity

speedofsound = 342.35 # (m/s) speed of sound

magVinf = J*RPM/60*(2*R)

Vinf(X, t) = magVinf*[cosd(AOA), sind(AOA), 0] # (m/s) freestream velocity vector

ReD = 2*pi*RPM/60*R * rho/mu * 2*R # Diameter-based Reynolds number

Matip = 2*pi*RPM/60*R / speedofsound # Tip Mach number

println("""

RPM: $(RPM)

Vinf: $(Vinf(zeros(3), 0)) m/s

Matip: $(round(Matip, digits=3))

ReD: $(round(ReD, digits=0))

""")

# ----------------- SOLVER PARAMETERS ------------------------------------------

# Aerodynamic solver

VehicleType = uns.UVLMVehicle # Unsteady solver

# VehicleType = uns.QVLMVehicle # Quasi-steady solver

const_solution = VehicleType==uns.QVLMVehicle # Whether to assume that the

# solution is constant or not

# Time parameters

nrevs = 4 # Number of revolutions in simulation

nsteps_per_rev = 36 # Time steps per revolution

nsteps = const_solution ? 2 : nrevs*nsteps_per_rev # Number of time steps

ttot = nsteps/nsteps_per_rev / (RPM/60) # (s) total simulation time

# VPM particle shedding

p_per_step = 2 # Sheds per time step

shed_starting = true # Whether to shed starting vortex

shed_unsteady = true # Whether to shed vorticity from unsteady loading

max_particles = ((2*n+1)*B)*nsteps*p_per_step + 1 # Maximum number of particles

# Regularization

sigma_rotor_surf= R/40 # Rotor-on-VPM smoothing radius

lambda_vpm = 2.125 # VPM core overlap

# VPM smoothing radius

sigma_vpm_overwrite = lambda_vpm * 2*pi*R/(nsteps_per_rev*p_per_step)

# Rotor solver

vlm_rlx = 0.7 # VLM relaxation <-- this also applied to rotors

hubtiploss_correction = vlm.hubtiploss_nocorrection # Hub and tip loss correction

# VPM solver

vpm_viscous = vpm.Inviscid() # VPM viscous diffusion scheme

# NOTE: In most practical situations, open rotors operate at a Reynolds number

# high enough that viscous diffusion in the wake is negligible.

# Hence, it does not make much of a difference whether we run the

# simulation with viscous diffusion enabled or not.

if VehicleType == uns.QVLMVehicle

# NOTE: If the quasi-steady solver is used, this mutes warnings regarding

# potential colinear vortex filaments. This is needed since the

# quasi-steady solver will probe induced velocities at the lifting

# line of the blade

uns.vlm.VLMSolver._mute_warning(true)

end

# ----------------- 1) VEHICLE DEFINITION --------------------------------------

println("Generating geometry...")

# Generate rotor

rotor = uns.generate_rotor(rotor_file; pitch=pitch,

n=n, CW=CW, blade_r=r,

altReD=[RPM, J, mu/rho],

xfoil=xfoil,

ncrit=ncrit,

data_path=data_path,

verbose=true,

verbose_xfoil=false,

plot_disc=true

);

println("Generating vehicle...")

# Generate vehicle

system = vlm.WingSystem() # System of all FLOWVLM objects

vlm.addwing(system, "Rotor", rotor)

rotors = [rotor]; # Defining this rotor as its own system

rotor_systems = (rotors, ); # All systems of rotors

wake_system = vlm.WingSystem() # System that will shed a VPM wake

# NOTE: Do NOT include rotor when using the quasi-steady solver

if VehicleType != uns.QVLMVehicle

vlm.addwing(wake_system, "Rotor", rotor)

end

vehicle = VehicleType( system;

rotor_systems=rotor_systems,

wake_system=wake_system

);

# NOTE: Through the `rotor_systems` keyword argument to `uns.VLMVehicle` we

# have declared any systems (groups) of rotors that share a common RPM.

# We will later declare the control inputs to each rotor system when we

# define the `uns.KinematicManeuver`.

# ------------- 2) MANEUVER DEFINITION -----------------------------------------

# Non-dimensional translational velocity of vehicle over time

Vvehicle(t) = zeros(3)

# Angle of the vehicle over time

anglevehicle(t) = zeros(3)

# RPM control input over time (RPM over `RPMref`)

RPMcontrol(t) = 1.0

angles = () # Angle of each tilting system (none)

RPMs = (RPMcontrol, ) # RPM of each rotor system

maneuver = uns.KinematicManeuver(angles, RPMs, Vvehicle, anglevehicle)

# NOTE: `FLOWUnsteady.KinematicManeuver` defines a maneuver with prescribed

# kinematics. `Vvehicle` defines the velocity of the vehicle (a vector)

# over time. `anglevehicle` defines the attitude of the vehicle over time.

# `angle` defines the tilting angle of each tilting system over time.

# `RPM` defines the RPM of each rotor system over time.

# Each of these functions receives a nondimensional time `t`, which is the

# simulation time normalized by the total time `ttot`, from 0 to

# 1, beginning to end of simulation. They all return a nondimensional

# output that is then scaled by either a reference velocity (`Vref`) or

# a reference RPM (`RPMref`). Defining the kinematics and controls of the

# maneuver in this way allows the user to have more control over how fast

# to perform the maneuver, since the total time, reference velocity and

# RPM are then defined in the simulation parameters shown below.

# ------------- 3) SIMULATION DEFINITION ---------------------------------------

Vref = 0.0 # Reference velocity to scale maneuver by

RPMref = RPM # Reference RPM to scale maneuver by

Vinit = Vref*Vvehicle(0) # Initial vehicle velocity

Winit = pi/180*(anglevehicle(1e-6) - anglevehicle(0))/(1e-6*ttot) # Initial angular velocity

simulation = uns.Simulation(vehicle, maneuver, Vref, RPMref, ttot;

Vinit=Vinit, Winit=Winit);

# ------------- 4) MONITORS DEFINITIONS ----------------------------------------

figs, figaxs = [], [] # Figures generated by monitor

# Generate rotor monitor

monitor_rotor = uns.generate_monitor_rotors(rotors, J, rho, RPM, nsteps;

t_scale=RPM/60, # Scaling factor for time in plots

t_lbl="Revolutions", # Label for time axis

out_figs=figs,

out_figaxs=figaxs,

save_path=save_path,

run_name=run_name,

figname="rotor monitor",

)

# ------------- 5) RUN SIMULATION ----------------------------------------------

println("Running simulation...")

uns.run_simulation(simulation, nsteps;

# ----- SIMULATION OPTIONS -------------

Vinf=Vinf,

rho=rho, mu=mu, sound_spd=speedofsound,

# ----- SOLVERS OPTIONS ----------------

p_per_step=p_per_step,

max_particles=max_particles,

vpm_viscous=vpm_viscous,

sigma_vlm_surf=sigma_rotor_surf,

sigma_rotor_surf=sigma_rotor_surf,

sigma_vpm_overwrite=sigma_vpm_overwrite,

vlm_rlx=vlm_rlx,

hubtiploss_correction=hubtiploss_correction,

shed_unsteady=shed_unsteady,

shed_starting=shed_starting,

extra_runtime_function=monitor_rotor,

# ----- OUTPUT OPTIONS ------------------

save_path=save_path,

run_name=run_name,

);

# ----------------- 6) VISUALIZATION -------------------------------------------

if paraview

println("Calling Paraview...")

# Files to open in Paraview

files = joinpath(save_path, run_name*"_pfield...xmf;")

for bi in 1:B

global files

files *= run_name*"_Rotor_Blade$(bi)_loft...vtk;"

files *= run_name*"_Rotor_Blade$(bi)_vlm...vtk;"

end

# Call Paraview

run(`paraview --data=$(files)`)

end

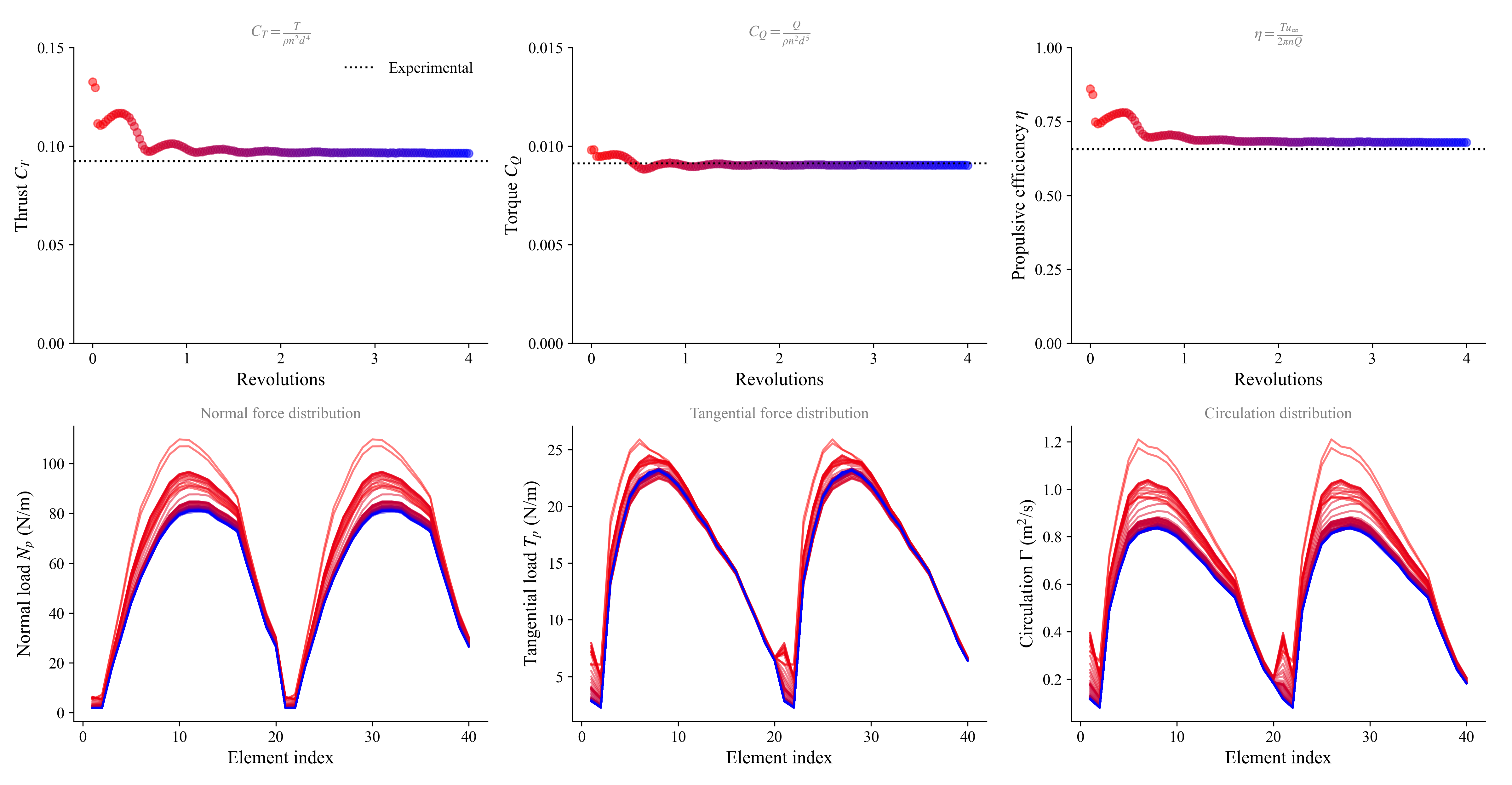

As the simulation runs, you will see the monitor shown below plotting the blade loading along with thrust and torque coefficients and propulsive efficiency.